LPN Plate Mill Testing Laboratory was established since March, 1995 to test mechanical and chemical properties, to perform analysis of macroscopic structure of steel, including several types of non-destructive tests to meet international standards. LPN Plate Mill Testing Laboratory

has been approved by ISO/IEC 17025 for measuring tensile strength, impact strength, bendability and analysis of chemical composition of Iron and Steel according to ASTM standards.

Mechanical Test

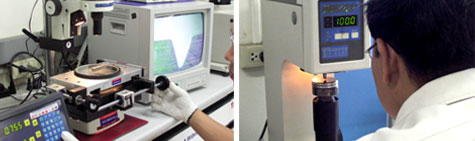

LPN provides the mechanical test to support the customer in various sectors especially in construction, petrochemical and fabrication industry.

With the specialized and trained persons and the high quality equipment so you can assure that you will get the high accuracy and precision result.

- TensionTest

- Bendability Test

- Impact Test

- Hardness Test

Nondestructive Testing

Rigid training for technicians and engineers were made and conducted by professionals with Ph.D. levels. Technicians for MPT, LPT and UT for Levels 2 in accordance with ASNT (American Society for Nondestructive Testing) are available to prepare a complete but comprehensive prognosis and analyses for test specimen in welding structure, pressure vessel, turbine blade, pipes, bridges and etc.

- Ultrasonic Test

- Magnetic Particle Test

- Liquid Penetrant Test

Chemical and Metallurgical analysis

Moreover LPN Plate Mill Testing Laboratory has expanded further its scope to further serve the needs and wants of the highly demanding market place in Thailand. The macro analyses of weld structure. Chemical analyses by spectrometer (SPECTROVAC) are calibrated using CRM materials (Certified Reference Materials). These activities ensure the accuracy and precision of our testing instrument.

- Chemical Analysis by Spectrometer

- Microstructure analysis